Can upgrade of a part of a system increase the whole process’s efficiency?

Our client uses a storage solution that utilizes space smart, but the storage solution limits access to resources in time. At a customer facility, multiple information systems need to be used to complete the job, besides physical work. Use of these systems adds time to the logistics process. Nothing can hinder a company's progress more than decreasing efficiency caused by inadequate technology.

What was the problem?

Employees doing job — processing orders were working. Still, their efficiency was limited because of a mess with order data printed on papers, received unsorted, a need of manually enter data on computers located on another workplace, etc.

Our goal was obvious…

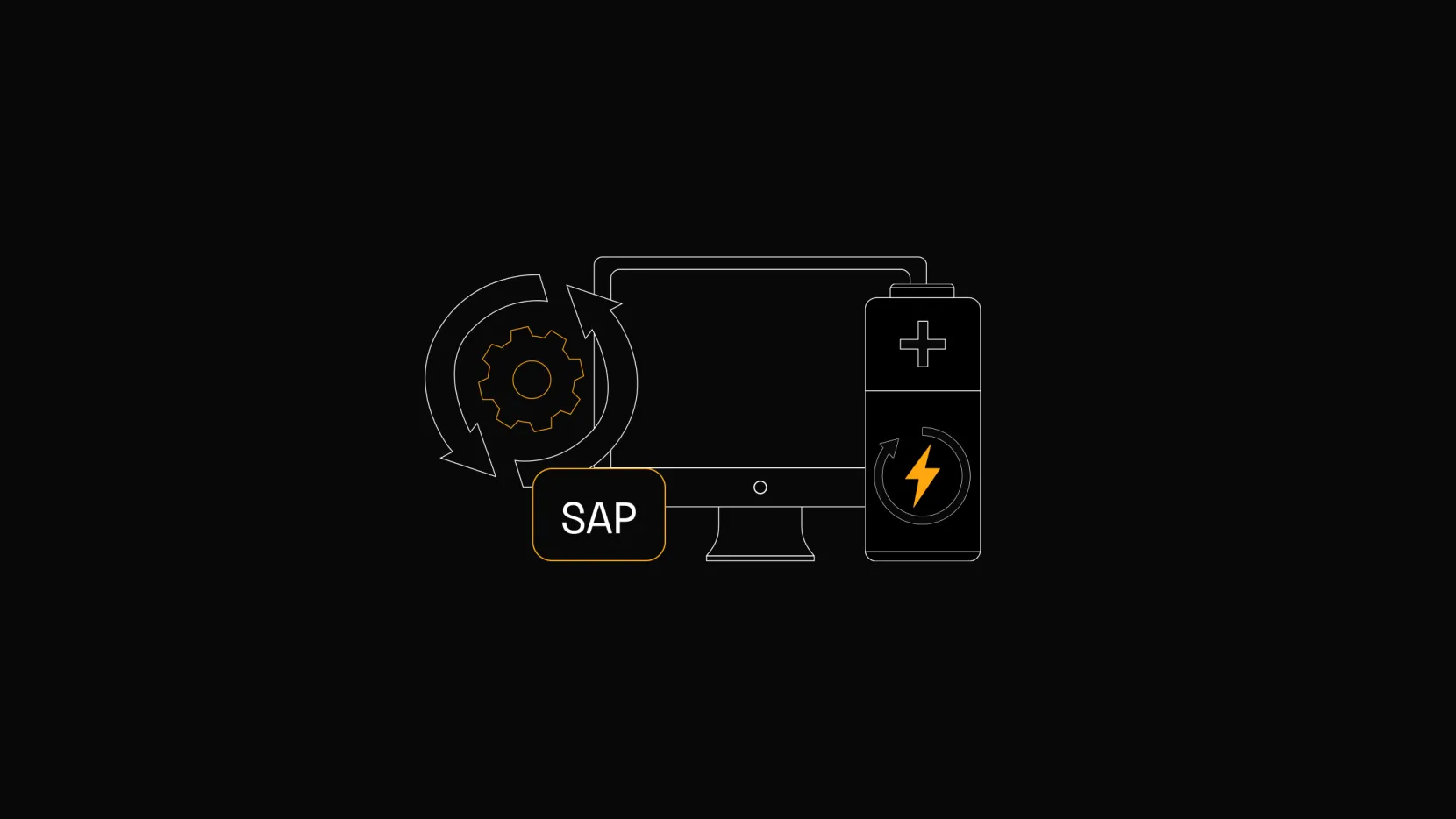

We aimed to reach a point where SAP would be the sole trusted source of real-time information, eliminating the need for additional synchronization between systems. Systems should share as much information as possible without user interaction, and if user interaction is necessary, data should be entered once and then synchronized across all required locations. When order is created in SAP it should be sent directly to the control system. Employees should be able to display order data with only the order ID and process it without leaving their current workplace. Order status data should be synchronized immediately between systems.

Solution where innovative hardware with smart custom software will met, had to come…

Lean-Lift — Vertical storage system

Due to rapidly evolving technology, there are ways to effectively utilize vertical space in a warehouse without the need for a forklift. Hänel Lean-Lift is the one used in a client’s facilities. It’s controlled by commands received from a controller. Communication is simple because the message contains only some information about the location of a shelf. At first, it moves the current shelf into its position and then it brings another one from the area in the last message.

Lean-Lift controller

Embedded computer (system) controls vertical storage system (Hänel Lean-Lift). It always displays actual data from SAP so employees can list all non-closed orders and see their states, find an order by its number, pick some item from that order and send a command to bring the right shelf.

SAP

Many companies use SAP as their Enterprise Resource Planning system. It’s very scalable, highly customizable, and, using integrations, it can be used as an all-in-one system since many external control systems contain SAP adapters/connectors.

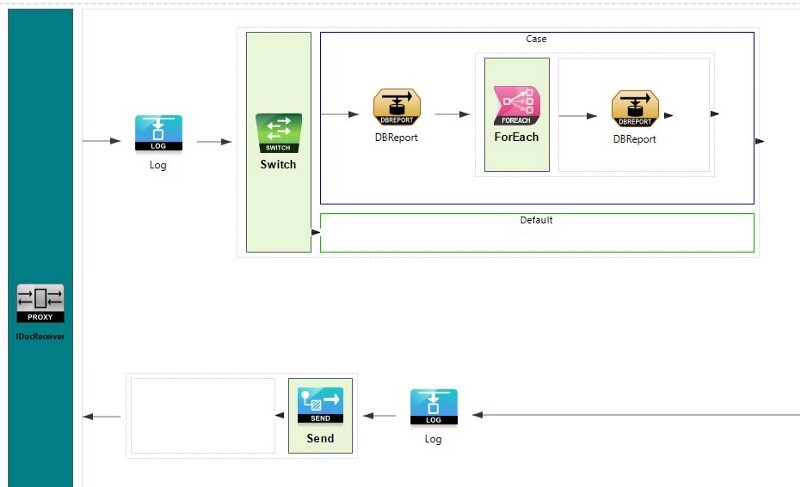

In our case, when an order is created in SAP, we receive it through a connector (proxy) and then process the message. After an action, the system sends a confirmation message back to SAP.

Kasys SW

Our SAP connector and additional business logic are implemented within WSO2 software, and specific parts are described in our previously published story „How to create a backend without programming using WSO2“.

Conclusion

We’ve developed a solution that has led to greater efficiency for the client’s company, as employees can now process more orders in less time. Upgrade of one part improved the entire process. There will be more to come as increasing efficiency is a continuous process. We will continue to work with the customer after this project is completed, as we both reveal more opportunities to improve efficiency as new integration ideas come to mind.